The Federation of Piling Specialists (FPS) has successfully delivered a great presentation to the Early Careers Group (ECG) on the much-requested topic of Grouting by Paul Marsden of Keller.

The seminar kicked off with a presentation about the many grouting processes, together with real-world examples of their application. Specifically, the presentation took attendees through the application of grout in engineering and the properties and benefits it brings such as:

• Reduces permeability

• Improves and/or extends existing foundations

• Controls settlement of structures

• Aids excavation stability

• Fills below surface voids

• Low mobility grout may be used to compact loose soil, e.g. solution features in chalk

The presentation then moved onto the types of grouting processes including Rock fissure grouting; Bulk filling; Hand lancing; Compaction grouting; Jet grouting; Hydrofracture grouting; and Compensation grouting. Choice of grout was also explained, with regards to soil conditions and the soil properties you should consider, including:

• Cement grouting – gravels

• Chemical grouting – sand

• Compaction grouting – sand

• Jet grouting – sand/gravels/silt/clay

• Fracture grouting– silt/clay

• Permeation – sand/gravel

Soilfrac grouting was also discussed and how it is used commonly in the UK to help re-level structures and around proposed tunnelling routes to control settlement.

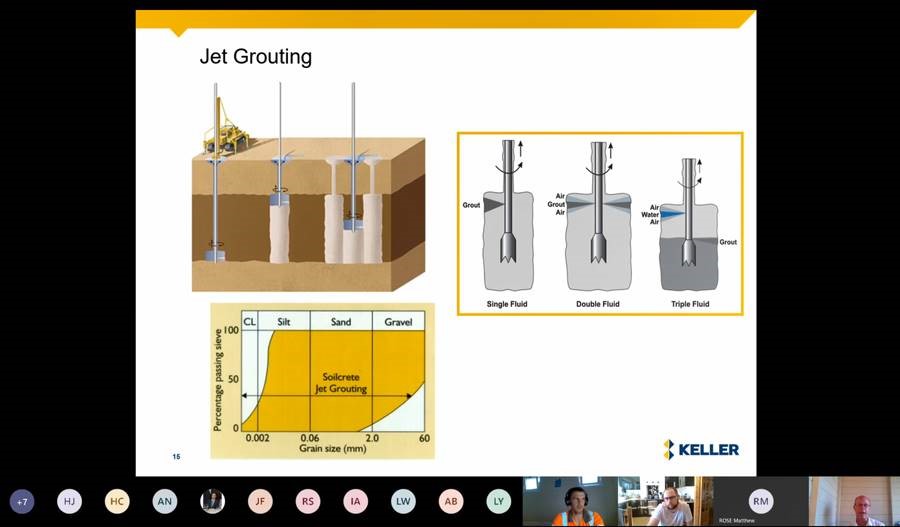

Time was also devoted to Jet Grouting and the three different types (See illustration); Single fluid – grout; Double fluid system – air & grout; and Triple fluid system – air & water & grout.

Throughout the presentation, examples were given where grouting methods had been used in the UK, with the most notable being, at permeation grouting at the Olympic Park, Stratford, jet grouting at Thames Tideway, Blackfriars Shaft and Victoria Station London, rock fissure grouting for shaft base slabs at Brighton, and compaction grouting of chalk solution features at Beaconsfield.

Questions were taken from the group, and Paul also explained that the depth of overlapping jet grout columns had previously been limited by borehole deviation with depth. The use of borehole survey tools had allowed deviation to be measured for different drill systems. This allowed analysis to be conducted to assess the risk of significant gaps and to find the optimum borehole spacing and jet grout column size. The limiting depth was once defined by the possibility of a gap. Now we can go deeper by calculating the probability of gaps of various sizes, conducting “as built” borehole surveys, and making an allowance for additional infill columns where the gap size is beyond acceptable limits.

A great presentation with tremendous feedback from all those who attended.

About Paul Marsden

Paul Marsden of Keller is a Chartered Engineer and a Fellow of the Institution of Civil Engineers. With over 26 years of broad geotechnical, civil and environmental engineering experience, his career has seen him manage all aspects of the construction process from project management, estimating, design and technical development, through to handover and post-completion, including major projects in the UK and abroad.

As a core member of Keller’s Global Product Team, Paul supports grouting processes across Europe, Middle East, Africa and South America, the Team promoting working with international colleagues to focus on sharing product-specific knowledge quickly around the world, to aid the development of market-leading technologies and solutions.